This post is also available in: Turkish Russian Arabic

NG Pedestal Boom Systems – Full Model Table (All Series)

| NG Code | Horizontal (Maximum Reach [mm]) | Vertical (Maximum Reach [mm]) | Weight [kg] | Max. Hammer Weight [kg] | Duty Class |

|---|---|---|---|---|---|

| NG-PB-LD1-1027 | 3170 mm | 1150 mm | 845 kg | 300 kg | Light Duty |

| NG-PB-LD2-2027 | 2700 mm | 2300 mm | 965 kg | 300 kg | Light Duty |

| NG-PB-LD2-2030 | 3000 mm | 2300 mm | 980 kg | - | Light Duty |

| NG-PB-LD2-2031 | 3100 mm | 2700 mm | 970 kg | - | Light Duty |

| NG-PB-LD2-2035 | 3500 mm | 2800 mm | 1000 kg | - | Light Duty |

| NG-PB-MD3-3027 | 2700 mm | 1800 mm | 2000 kg | 720 kg | Medium Duty |

| NG-PB-MD3-3033 | 3300 mm | 3400 mm | 1700 kg | - | Medium Duty |

| NG-PB-MD3-3035 | 3500 mm | 3800 mm | 1800 kg | - | Medium Duty |

| NG-PB-MD3-3036 | 3600 mm | 3700 mm | 1750 kg | - | Medium Duty |

| NG-PB-MD3-3042 | 4200 mm | 4700 mm | 2000 kg | - | Medium Duty |

| NG-PB-MD3-3043 | 4300 mm | 4000 mm | 2100 kg | - | Medium Duty |

| NG-PB-MD3-3052 | 5200 mm | 5200 mm | 2150 kg | 520 kg | Medium Duty |

| NG-PB-MD3-3057 | 5700 mm | 5400 mm | 2400 kg | - | Medium Duty |

| NG-PB-MD3-3061 | 6100 mm | 5900 mm | 2700 kg | - | Medium Duty |

| NG-PB-MD3-3062 | 6200 mm | 5100 mm | 2900 kg | - | Medium Duty |

| NG-PB-HD4-4046 | 4600 mm | 3000 mm | 4130 kg | 1200 kg | Heavy Duty |

| NG-PB-HD4-4057 | 5700 mm | 3500 mm | 4380 kg | - | Heavy Duty |

| NG-PB-HD4-4060 | 6000 mm | 3600 mm | 4450 kg | - | Heavy Duty |

| NG-PB-HD4-4064 | 6400 mm | 4700 mm | 4500 kg | - | Heavy Duty |

| NG-PB-HD4-4069 | 8650 mm | 4800 mm | 5050 kg | 1000 kg | Heavy Duty |

| NG-PB-HD4-4072 | 7200 mm | 6600 mm | 4790 kg | - | Heavy Duty |

| NG-PB-HD4-4076 | 7600 mm | 5500 mm | 4500 kg | - | Heavy Duty |

| NG-PB-HD4-4089 | 8900 mm | 8100 mm | 5100 kg | - | Heavy Duty |

| NG-PB-HD4-4101 | 10100 mm | 8900 mm | 5490 kg | - | Heavy Duty |

| NG-PB-XHD5-5050 | 5000 mm | 4200 mm | 5800 kg | 2000 kg | Extra Heavy Duty |

| NG-PB-XHD5-5060 | 6000 mm | 3600 mm | 5800 kg | - | Extra Heavy Duty |

| NG-PB-XHD5-5069 | 6900 mm | 5500 mm | 7100 kg | - | Extra Heavy Duty |

| NG-PB-XHD5-5085 | 8500 mm | 6400 mm | 7650 kg | 1700 kg | Extra Heavy Duty |

| NG-PB-XHD5-5089 | 8900 mm | 6900 mm | 8500 kg | - | Extra Heavy Duty |

| NG-PB-XHD5-5098 | 9800 mm | 8900 mm | 10800 kg | - | Extra Heavy Duty |

| NG-PB-XHD5-5108 | 10800 mm | 10000 mm | 11200 kg | - | Extra Heavy Duty |

| NG-PB-SHD6-6110 | 11100 mm | 8700 mm | 22200 kg | 2500 kg | Super Heavy Duty |

| NG-PB-SHD6-6128 | 12800 mm | 9100 mm | 23000 kg | - | Super Heavy Duty |

| NG-PB-SHD6-6130 | 13000 mm | 10150 mm | 23600 kg | 2000 kg | Super Heavy Duty |

| NG-PB-SHD6-6145 | 14450 mm | 11320 mm | 24000 kg | - | Super Heavy Duty |

| NG-PB-SHD6-6151 | 15100 mm | 10800 mm | 24350 kg | - | Super Heavy Duty |

| NG-PB-SHD6-6155 | 15550 mm | 12200 mm | 24700 kg | - | Super Heavy Duty |

| NG-PB-SHD6-6168 | 16800 mm | 12800 mm | 26500 kg | 3100 kg | Super Heavy Duty |

| NG-PB-SHD6-6174 | 17400 mm | 13800 mm | 27300 kg | - | Super Heavy Duty |

| NG-PB-UHD-7167 | 16700 mm | 12770 mm | 29700 kg | 3100 kg | Ultra Heavy Duty |

| NG-PB-UHD-7176 | 17600 mm | 13500 mm | 31000 kg | 3100 kg | Ultra Heavy Duty |

Hydraulic Pedestal Boom Systems

Hydraulic pedestal boom systems from NG Attachments are engineered to keep crushers running safely and efficiently by eliminating oversized rock blockages at the feed opening. Designed for primary and secondary breaking in quarries, mines and heavy-duty industrial plants, these stationary boom and hammer systems provide precise control, extended working reach and excellent impact resistance under continuous 24/7 operation.

Each pedestal boom is built from high-strength welded steel, with optimized boom geometry and heavy-duty hydraulic cylinders to deliver maximum stability during rock breaking. By positioning a hydraulic breaker directly above the crusher mouth or grate, NG pedestal boom systems significantly reduce downtime, improve material flow and increase overall plant productivity while enhancing operator and equipment safety.

Applications of NG Hydraulic Pedestal Booms

- Primary breaking at jaw and impact crushers in stone quarries

- Secondary breaking above grizzlies, hoppers and chutes

- Continuous rock breaking on stationary cone crushers

- Underground mine installations for safe drawpoint management

- Slag handling and oversized material control in metal and steel plants

- Cement plants and aggregate production facilities requiring 24/7 reliability

Key Features of NG Pedestal Boom Systems

- Light-duty, medium-duty, heavy-duty and super heavy-duty boom configurations

- Optimized reach for small, medium and large crusher stations

- Robust boom sections with high mechanical resistance and low deflection

- Heavy-duty pivot points and pins for long service life

- Accurate, smooth positioning for rock breaker tools

- Compatibility with hydraulic hammers up to the super heavy range

- Electric-hydraulic power units with efficient cooling and protection

- Optional radio remote control and ergonomic operator consoles

Benefits for Quarries, Mines and Industrial Plants

Implementing an NG pedestal boom system directly above the crusher brings immediate operational and safety benefits. Oversized boulders no longer need to be handled with mobile equipment close to the feed opening, which reduces the risk of accidents and mechanical damage. The crusher can work with a more consistent feed size, leading to higher throughput, more stable power consumption and a better overall product curve.

- Reduced unscheduled shutdowns due to blocked crusher inlets

- Safer working environment around the crusher station

- Higher utilisation of primary and secondary crushers

- Lower maintenance costs on crusher liners and components

- Improved overall plant productivity and energy efficiency

Compatibility with Hydraulic Breakers and Plants

NG hydraulic pedestal boom systems are designed to work with a wide selection of hydraulic rock breakers from leading brands. Depending on the duty class, NG pedestal booms can be configured for breakers from compact models used on small jaw crushers up to super heavy-duty hammers for large stationary cone crushers and extreme-duty grate work.

- Compatible with major breaker brands and sizes (light to super heavy)

- Custom mounting brackets and adapter plates on request

- Integration with existing crusher control systems is possible

- Engineered support for foundation design and installation details

Made in Türkiye – Engineered for Extreme Conditions

All NG hydraulic pedestal boom systems are designed and manufactured in Türkiye by NG Attachments, using certified materials and international welding standards. Every boom structure, pedestal column and power unit is assembled according to technical drawings and undergoes strict quality control to ensure reliable performance in tough quarry and mining environments.

NG Attachments delivers pedestal booms for customers who demand robust construction, long service life and fast service support. Whether you are planning a new crusher installation or upgrading an existing plant, NG engineers can help you select the correct duty class and reach configuration for your application.

FAQ – Hydraulic Pedestal Boom Systems

1. What is a hydraulic pedestal boom system?

A hydraulic pedestal boom system is a stationary boom with a mounted hydraulic rock breaker, installed above a crusher, hopper or grate. It is used to break oversized rocks and prevent crusher blockages without moving mobile equipment close to the feed opening.

2. Where are NG pedestal boom systems typically installed?

NG pedestal booms are typically installed at primary jaw crushers, impact crushers, cone crushers, grizzlies and hoppers in stone quarries, mines, cement plants and metal processing facilities.

3. Can NG pedestal boom systems work with my existing hydraulic breaker?

In many cases yes. NG engineers match the boom duty class and reach to your existing breaker size and crusher layout. When required, adapter plates and brackets are supplied to connect your breaker safely to the NG pedestal boom.

4. Are the systems suitable for continuous 24/7 operation?

Yes. NG pedestal boom systems are designed for continuous use in demanding quarry and mining conditions, with heavy-duty structures, high-quality hydraulics and properly sized power units.

5. How can I choose the right pedestal boom size for my crusher?

Selection depends on crusher type, feed opening, required working envelope and breaker size. Share your plant layout and operating conditions with NG Attachments and our engineering team will recommend the correct boom reach and duty class.

Application for NG Hydraulic Pedestal Boom Systems

NG hydraulic pedestal boom systems are designed for primary and secondary rock breaking at crusher stations, grizzlies and hoppers. They are used in quarries, mines, aggregate and cement plants wherever oversized rock must be safely reduced before entering the crusher. By positioning a hydraulic breaker above the crusher mouth or grate, the system improves safety, increases productivity and reduces unplanned downtime.

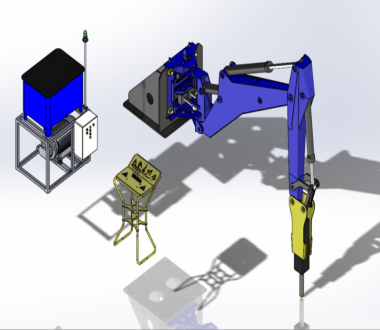

Accessories – Operator’s Station

Standard Remote Controls

The operator’s station is equipped with standard remote controls and connected to the pedestal boom system via a dedicated control cable. This configuration allows the operator to perform all movements and breaker operations from a safe location with an excellent view of the rock breaking area, significantly increasing both safety and precision at the crusher station.

Remote-Control Operator’s Station

As an option, a remote-control operator’s station can be supplied. The remote console allows the operator to position themselves at any safe vantage point with the best visibility of the feed opening and grate. This configuration further improves operator comfort, reaction time and overall control of the rock breaking process.

Accessories – Steel Boom Structure

The pedestal boom is manufactured from a high-strength steel structure with a robust, welded frame designed for heavy-duty and continuous use. Optional reinforcements, wear plates and special configurations can be supplied depending on the duty class and working conditions. The manufacturer reserves the right to change these parameters as part of continuous product development.

Accessories – Hydraulic Drive Unit

Hydraulic drive units are designed specifically for demolition and rock breaking equipment. The model, displacement and output of each drive unit are defined according to the hydraulic breaker in use and the size of the pedestal boom system. Each unit typically includes the hydraulic pump, electric motor, oil tank, filtration, safety components and, where necessary, an oil cooler for continuous duty applications.

The manufacturer reserves the right to change these parameters and specifications without prior notice in order to improve performance and reliability.

Accessories – Operator’s Cab

Various configurations of the operator’s cab are available to increase operator comfort and protection. Enclosed cabs isolate the operator from harmful external conditions such as noise, dust, vibration, cold and hot temperatures. Depending on the project, the cab can be equipped with ergonomic seats, integrated control consoles, heating and air conditioning, safety glazing and LED lighting to ensure safe and efficient operation in demanding quarry and mining environments.