| NG Code | Weight (kg) | Jaw Opening (mm) | Jaw Depth (mm) | Reach (m) | Min Excavator Weight (t) |

|---|---|---|---|---|---|

| NG-DP-2400-CP | 2,400 | 640 | 690 | 3.0 | 18 |

| NG-DP-3200-CP | 3,200 | 710 | 760 | 2.9 | 25 |

| NG-DP-4100-CP | 4,100 | 860 | 910 | 3.4 | 32 |

| NG-DP-6300-CP | 6,300 | 1,270 | 1,140 | 4.0 | 45 |

| NG Code | Weight (kg) | Jaw Opening (mm) | Jaw Depth (mm) | Reach (m) | Min Excavator Weight (t) |

|---|---|---|---|---|---|

| NG-DP-2100-CC | 2,100 | 640 | 690 | 3.0 | 18 |

| NG-DP-2900-CC | 2,900 | 810 | 790 | 2.9 | 25 |

| NG-DP-3700-CC | 3,700 | 970 | 910 | 3.4 | 32 |

| NG-DP-5600-CC | 5,600 | 1,270 | 1,140 | 4.0 | 45 |

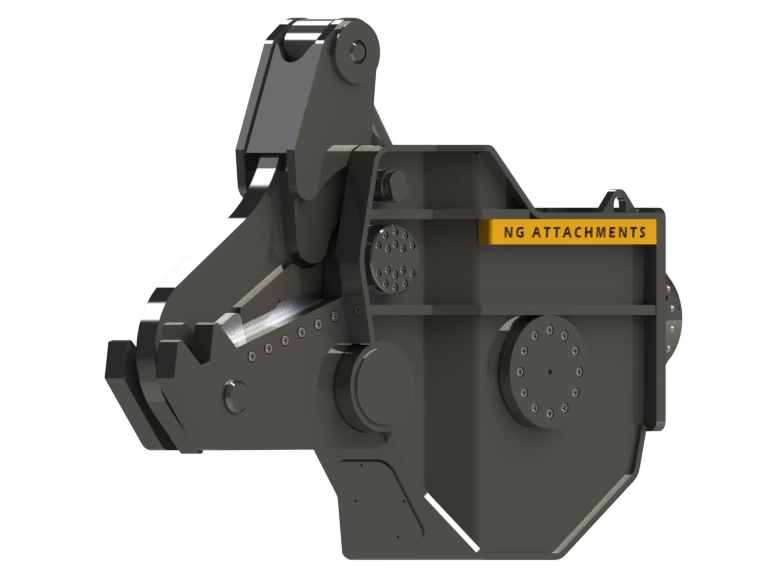

Demolition Processor for Excavators (Concrete Pulverizer & Concrete Cracking) – NG Attachments

NG Demolition Processor attachments are engineered for professional demolition contractors who need reliable performance in reinforced concrete demolition, material separation, and recycling operations. Built for excavator mounting, the NG processor combines strong structural design with optimized jaw geometry to deliver consistent crushing and cracking efficiency across demanding job sites.

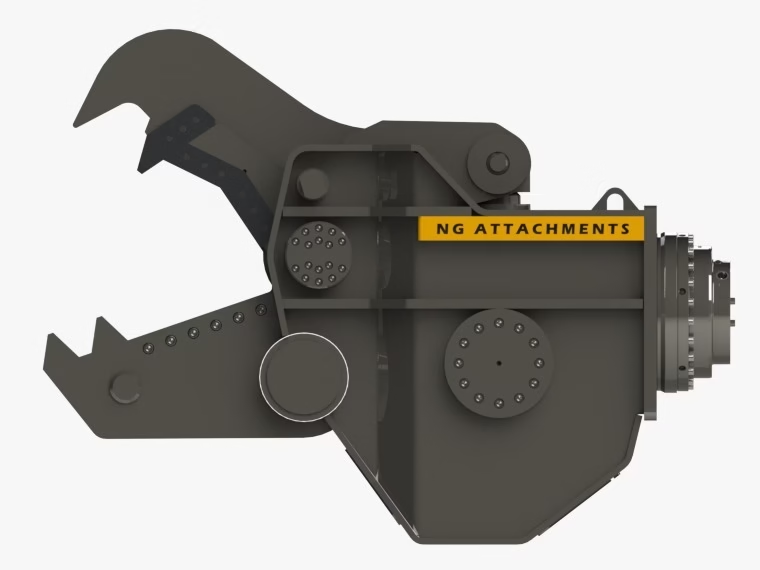

This product range is offered with two dedicated jaw configurations: a Concrete Pulverizer jaw for efficient concrete crushing and steel separation, and a Concrete Cracking jaw for controlled breaking and selective demolition. By choosing the right jaw type for the task, operators can improve productivity, reduce handling time, and achieve cleaner separation of concrete and rebar for downstream recycling.

Key Advantages of NG Demolition Processor Attachments

- Designed for heavy-duty demolition and concrete recycling applications

- Optimized jaw opening and depth for productive bite and material control

- Suitable for primary and secondary demolition workflows

- Supports cleaner separation of concrete and rebar to improve recycling efficiency

- Built with durability-focused engineering for long service life in harsh environments

Applications

- Building demolition and structural dismantling

- Reinforced concrete crushing and rebar separation

- Bridge and infrastructure demolition projects

- Concrete recycling yards and waste handling facilities

- Selective demolition in urban job sites

Excavator Compatibility

NG demolition processors can be configured for a wide range of excavator classes. Carrier weight recommendations depend on the mounting arrangement, hydraulic setup, coupler type, arm length, and job conditions. For accurate selection and safe operation, NG engineers confirm compatibility based on the excavator model and application requirements.

Compatible with excavators from leading brands such as CAT, Komatsu, Hitachi, Volvo, Hyundai, Doosan, JCB, Liebherr, SANY, XCMG, CASE, Kobelco, and more.

Why Choose NG Attachments

NG Attachments is a Turkish manufacturer with its own production facility. Every demolition processor is manufactured in Türkiye to European engineering and quality standards, focusing on durability, precision, and dependable performance. This approach helps contractors reduce downtime, maintain steady output, and operate confidently in high-impact demolition environments.

If you need a demolition processor for concrete pulverizing or concrete cracking, contact NG Attachments to select the right configuration for your excavator and your project scope.

Request a Quote

Share your excavator model, operating weight, hydraulic flow/pressure, and target application (pulverizing or cracking). Our team will recommend the best NG configuration.

FAQ

What is a demolition processor used for?

A demolition processor is used for crushing reinforced concrete, breaking structures, and separating concrete from rebar to improve recycling and job-site efficiency.

Which jaw type should I choose: Concrete Pulverizer or Concrete Cracking?

Choose the Concrete Pulverizer jaw when you want strong crushing and cleaner rebar separation. Choose the Concrete Cracking jaw when you need controlled breaking, selective demolition, and efficient cracking performance on concrete structures.

How do I select the right demolition processor for my excavator?

Selection depends on excavator operating weight, mounting position, hydraulic specifications, coupler type, and job requirements. Send your excavator details to NG Attachments for a precise recommendation.